Yarn Count Explained: Everything You Need to Know

November 11, 2024 | Yarn

Welcome to our comprehensive guide on yarn count, where we dive deep into everything you need to know about this crucial aspect of textiles. Whether you're a seasoned professional in the textile industry or a knitting enthusiast ready to dive into your next project, understanding yarn count is essential for choosing the right yarn for your projects.

In this article, we will explore the ins and outs of yarn count, including its definition, different yarn count systems, yarn count conversion and how it affects the overall quality and appearance of fabrics and garments. We'll delve into why we need to count yarn count, difference between yarn and thread count and the significance of yarn counts in different applications. Ready to unravel the mysteries of yarn count? Let's get started!

What is Yarn Count?

Simply put, yarn count is a number that indicates the thickness or fineness of a yarn. It’s a key quality parameter that indicates the linear density or mass per unit length of yarn, expressed as a ratio of length to weight or weight to length. Yarn count reflects the yarn's fineness, coarseness, or overall size, with thinner yarns producing lighter, finer, and softer fabrics, while thicker yarns result in heavier and coarser fabrics.

Why is Yarn Count Important?

Almost all the yarn produced in the world gets converted into fabric. Yarn count is important in the textile industry because manufacturers, fashion designers, and those involved in producing textile heavily rely on yarn count for quality control and product development. Here are some key reasons why yarn count is so important in textile manufacturing:

Determining Fabric Thickness

Almost all the yarn produced in the world gets converted into either fabric or final garment products like sweater. Textile manufacturers, garment producers, fashion designers, and those involved in producing fabrics or yarn-based products heavily rely on yarn count for quality control and product development. Yarn count impacts fabric properties like thickness, softness, strength, quality, weight, comfort, and fluidity. It also influences the appearance and texture of the fabric.

What are the Yarn Count Systems?

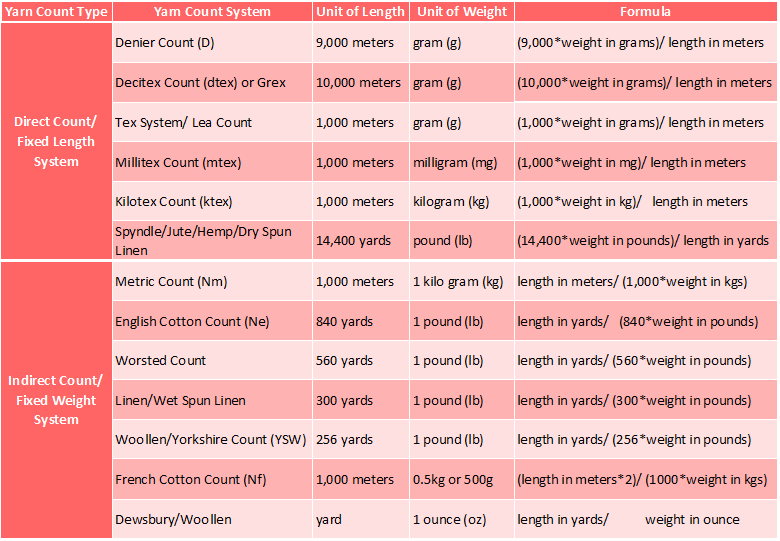

The count can be classified into two types of count systems based on natural and manmade fiber.

-

Direct count system

-

Indirect count system

Direct Count System is generally used for synthetic fiber, jute, silk etc. The common features of aII direct count systems are the length of yarn is fixed and the weight of yarn varies according to its fineness. Thus, higher the count, coarser the yarn.

The indirect Yarn Count System expresses the number of length units in one weight unit. So, higher the count, finer the yarn. It’s generally used for cotton, worsted, linen (wet spun) etc.

Yarn Count Formula

Different system or units are used to measuring the yarn count, depending on the material used and the area where the yarn was manufactured. Here are the yarn count formulas:

Yarn count conversion

Converting yarn count from one system to another makes it easy to verify the values of a yarn count in the different units of measurement. To convert any yarn count system into your desired one, use our yarn count converter calculator.

How to interpret the yarn count?

Yarn counts are usually expressed as two numbers separated by a slash, followed by the count system abbreviation. For example, 16/2 nm or 2/16 wc. The bigger number is the count, which indicates the length of yarn for a given weight. The other number is usually smaller and indicates how many strands of yarn have been plied together.

Another way of expressing yarn count is to express the value in terms of the grams (of yarn) per km, known as the tex of a yarn. The bigger the number, the thicker the yarn. The smaller the number, the finer the yarn.

Yarn count in different textile applications

Selecting the appropriate yarn count is vital in achieving the desired characteristics in the final product. Here’s how to choose the right yarn count based on textile application:

Apparel

For light, breathable fabrics like t-shirts, blouses, or summer dresses, high-count cotton yarns (Ne 40 and above) work well. For sturdier items like jeans or jackets, lower counts (Ne 10-20) provide more strength and durability.

Home Textiles

For bedsheets or drapery, finer yarns (Ne 40 and above) provide smoothness and elegance, while table linens and upholstery benefit from thicker yarns with lower counts.

Industrial Use

Applications requiring durability and resilience, such as ropes, carpets, or industrial fabrics, use low-count yarns for enhanced strength.

Yarn vs. Thread – Are they same?

Yarn count and thread count are terms that are often confused for being the same. Although both are related properties, it’s not the same. Yarn count, as we have already established, refers to the thickness of the individual threads used to weave the fabric. Whereas, thread count refers to the total number of threads (both vertical and horizontal) woven into a square inch of fabric. A higher thread count generally implies a smoother and denser fabric. Both metrics are important but serve different purposes in fabric assessment.

Conclusion

Understanding yarn count is invaluable for anyone involved in textile production or sourcing. By mastering this concept, you gain greater control over the properties of the fabrics you work with. Yarn count serves as a guide to selecting the right yarn for every application, helping you achieve desired fabric qualities and meet market demands.

Empty Cart

Empty Cart